Pack lithium battery production implementation standards

Welcome to our dedicated page for Pack lithium battery production implementation standards! Here, we have carefully selected a range of videos and relevant information about Pack lithium battery production implementation standards, tailored to meet your interests and needs. Our services include high-quality Pack lithium battery production implementation standards-related products and solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to Pack lithium battery production implementation standards, including cutting-edge solar energy storage systems, advanced lithium-ion batteries, and tailored solar-plus-storage solutions for a variety of industries. Whether you're looking for large-scale industrial solar storage or residential energy solutions, we have a solution for every need. Explore and discover what we have to offer!

Guidance Manual for Battery Manufacturing Pretreatment

Section 403.12(b) requires that BMRs be submitted to the Control Authority within 180 days after the effective date of a newly promulgated categorical pretreatment standard or 180 days after

WhatsApp

UL Certifications for Lithium Batteries: Cell vs. Pack Level – What

Safety is paramount in the world of lithium batteries. One of the most recognized and trusted safety standards is UL certification. However, not all UL certifications are created

WhatsApp

Production requirements of lithium battery PACK manufacturers

PACK includes battery pack, bus bar, soft connection, protective board, outer packaging, output, highland barley paper, plastic bracket and other auxiliary materials to form

WhatsApp

Standards specific to the battery manufacturing industry

What standards are specific to the battery manufacturing industry? 1. European battery regulations. 2. The IEC standard. 3. ECHA (European Chemicals Agency) regulation. 4. US

WhatsApp

Battery circularity in India: Policy, regulations, and

hinder the development of a safe and sustainable circular economy for batteries. These include the lack of circularity-friendly battery design, implementation issues in the EPR provisions, lack

WhatsApp

Custom Lithium Battery Pack Manufacturing

Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent

WhatsApp

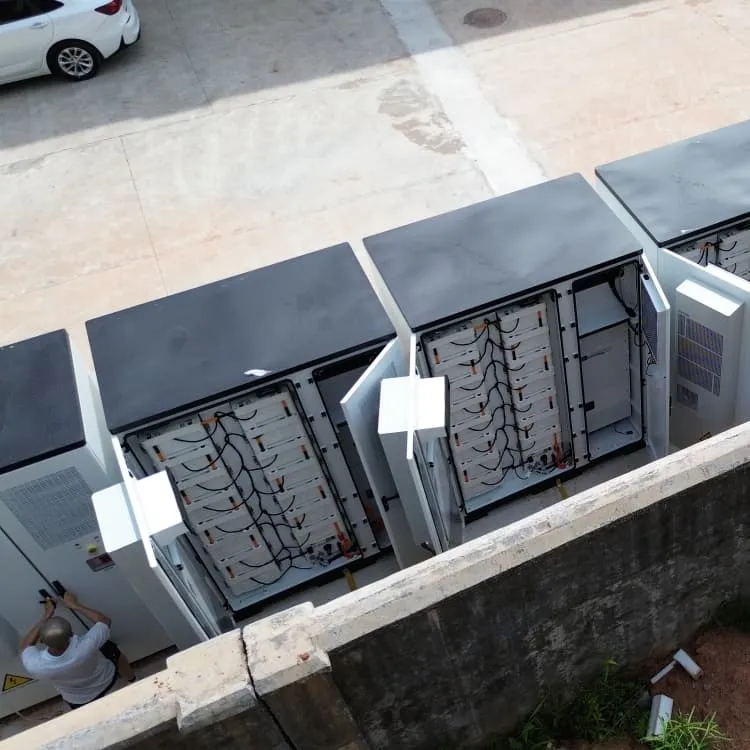

PRODUCTION PROCESS OF BATTERY MODULES AND

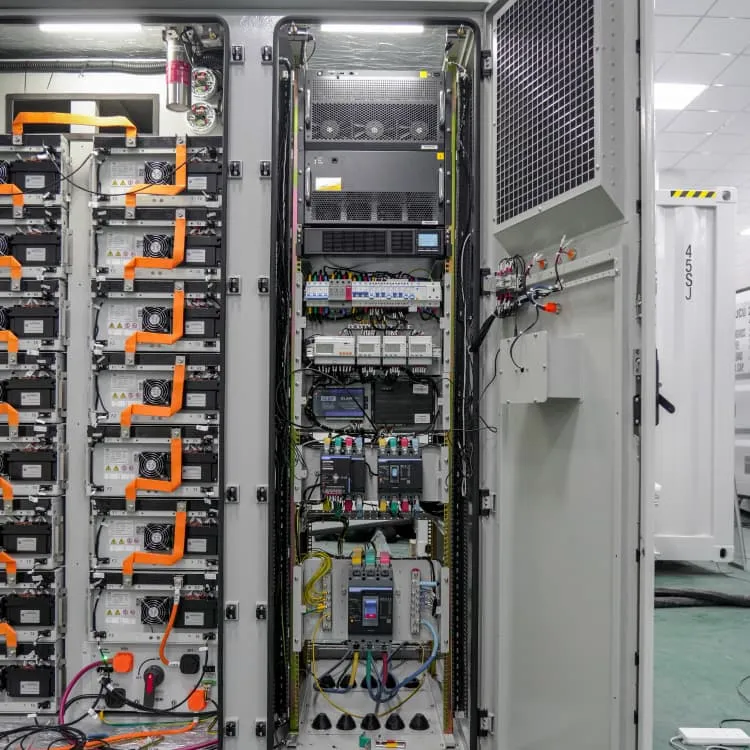

Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain. Overview of the production sequence from cell to system. 60% 80%

WhatsApp

Custom Lithium Ion Battery Packs vs Off-the-Shelf: What

Contact our team for inquiries about both custom and standard battery packs to determine the most cost-effective solution for your project. When the investment in a custom

WhatsApp

Battery Regulations in the US: A Comprehensive Overview

US battery regulations focus on safety, environmental protection, and performance standards. Federal agencies like the EPA and DOT oversee recycling, transportation, and

WhatsApp

Current and future lithium-ion battery manufacturing

Here in this perspective paper, we introduce state-of-the-art manufacturing technology and analyze the cost, throughput, and energy consumption based on the production processes.

WhatsApp

The Fundamentals of Battery/Module Pack Test

The Importance of Battery Module and Pack Testing The battery market is growing rapidly due to the acceleration of electrification in the automotive, aerospace and energy industries. In turn,

WhatsApp

The Fundamentals of Battery/Module Pack Test

By 2030, the annual lithium-ion battery demand for EVs is estimated to surpass 1,748 GWh annually. As a result of decreasing battery costs, global energy storage installations are also

WhatsApp

Advanced lithium-ion battery process manufacturing equipment

Summary Lithium-ion battery cell manufacturing depends on a few key raw materials and equipment manufacturers. Battery manufacturing faces global challenges and

WhatsAppFAQs 6

What are the UL standards for lithium ion batteries?

UL Standards are among the most widely recognized battery safety standards in the USA. They cover various aspects of battery manufacture and use, including : This standard concerns the safety of lithium-ion battery cells. It includes short-circuit, overcharge, excessive discharge and temperature tests to ensure the safety of individual cells.

What are the safety standards for lithium ion batteries?

This standard concerns the safety of lithium-ion battery cells. It includes short-circuit, overcharge, excessive discharge and temperature tests to ensure the safety of individual cells. This standard applies to batteries used in household and commercial appliances.

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

What are the transportation requirements for lithium & lead batteries?

The transportation of batteries, particularly lithium and lead batteries, is subject to federal regulations on the transportation of dangerous goods (TDG). Requirements include: All battery shipments must comply with TDG Act requirements.

Why do custom lithium-ion batteries need a lifecycle mindset?

Once produced, properly supporting packs throughout service life is paramount: This lifecycle mindset maximizes the ROI of custom lithium-ion battery investments. Working with lithium-ion cells and batteries necessitates rigorous safety protocols given flammability risks if improperly handled.

More industry content

- The largest energy storage battery pack

- 6kw solar panels with energy storage batteries

- Which solar photovoltaic panel is best

- Serbia lithium battery energy storage project construction

- Can an inverter be used for outdoor power supply

- Congo Brazzaville outdoor energy storage project

- Can a single solar panel drive a water pump inverter

- Syria high-frequency inverter

- Communication base station power supply outside the window

- Price of photovoltaic energy storage power station

- Huawei communication base station inverter supply cut off

- Direct-mounted energy storage power station design

- Grid-connected inverter output protection

- 3 7V Lithium Battery Inverter

- Can energy storage batteries discharge continuously

- 8kW solar panel price

- How much is the purchase price of the energy storage cabinet battery

- What is the price of photovoltaic panel electricity generation

- Mobile Base Station Power Supply NEEQ

- How many inverters are needed for a 90W photovoltaic system

- Double glass components for skylight tiles

- Eastern European Power Plant Energy Storage System Solutions