Borneo Pack Battery Assembly Plant

Welcome to our dedicated page for Borneo Pack Battery Assembly Plant! Here, we have carefully selected a range of videos and relevant information about Borneo Pack Battery Assembly Plant, tailored to meet your interests and needs. Our services include high-quality Borneo Pack Battery Assembly Plant-related products and solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to Borneo Pack Battery Assembly Plant, including cutting-edge solar energy storage systems, advanced lithium-ion batteries, and tailored solar-plus-storage solutions for a variety of industries. Whether you're looking for large-scale industrial solar storage or residential energy solutions, we have a solution for every need. Explore and discover what we have to offer!

A Comprehensive Guide To EV Car Battery Manufacturing Plant:

Car battery assembly plants are crucial components in the production of high-performance batteries for electric vehicles. In this detailed blog post, we will provide an in

WhatsApp

EV Battery Manufacturing | Electric Vehicle Battery Pack Process

6 days ago· In assembly processes, repeatable and accurate dispense is critical to meeting stringent production requirements at high volumes. For applications, such as cell to carrier

WhatsApp

SSOE Group | Battery Manufacturing | Battery Plant Design

Our proficiency is born from hands-on experience at the vanguard of a leading electric vehicle manufacturer''s plant, encompassing the entirety of battery assembly pack processes.

WhatsApp

Opening of Georgia EV battery plant to be delayed after ICE raid

18 hours ago· A top Hyundai official said an immigration raid on the HL-GA Battery plant under construction next to the Hyundai Metaplant will delay the facility''s opening.

WhatsApp

Mahindra & Mahindra Ltd mahindraRise

Mahindra Unveils New Dedicated State-of-the-art EV Manufacturing & Battery Assembly Facility in Chakan Pune, January 8, 2025: Mahindra today unveiled its new dedicated state-of-the-art

WhatsApp

Mastering the Battery Pack Assembly Process: A Comprehensive

Component Preparation: High-quality battery cells, BMS, wiring, and casings are inspected and prepared for assembly. Cell Assembly: Battery cells are arranged in series or

WhatsApp

Lithium-ion Battery Pack Manufacturing Process & Design

The battery pack assembly is the process of assembling the positive electrode, negative electrode, and diaphragm into a complete battery. This involves placing the

WhatsApp

JBM Group – Fully Automated Bus Battery Pack Assembly Line

Maestrotech, with its expertise in automation for battery pack assembly, undertook the challenge and delivered a first-of-its-kind fully automated assembly line for prismatic cell-based battery

WhatsApp

Essential Requirements For Establishing A EV Car Battery Assembly Plant

Building a Car Battery Manufacturing Plant requires careful consideration of various fundamental requirements. From infrastructure and skilled labor to advanced machinery and

WhatsApp

Battery Pack Manufacturing Machine,Battery Pack Compoment,Battery Pack

This customized production line is mainly used to complete the assembly, inspection, assembly, and welding functions of the prismatic cell energy storage battery pack module.

WhatsApp

Date 21st January, 2025 National Stock Exchange of India

State-of-the-art battery-pack assembly plant at Chennai, Tamil Nadu of-the-art battery-pack assembly plant in Chennai, Tamil Nadu, located within In phase 1, the plant has an annual

WhatsAppFAQs 6

What are the three parts of battery pack manufacturing process?

Battery Module: Manufacturing, Assembly and Test Process Flow. In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell Finishing. Article Link In this article, we will look at the Module Production part.

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What is battery pack assembly?

The battery pack assembly is the process of assembling the positive electrode, negative electrode, and diaphragm into a complete battery. This involves placing the electrodes in a cell casing, adding the electrolyte, and sealing the cell.

How will emerging technologies transform battery pack manufacturing?

Emerging technologies will transform battery pack manufacturing: These developments collectively point toward battery packs with higher energy density, longer lifespan, faster manufacturing times, and substantially improved environmental credentials.

What are the final stages of the battery pack manufacturing process?

The final stages of the battery pack manufacturing process involve careful handling, transportation, and implementation to ensure products reach their destination safely and function as intended. Battery packs require specialized packaging to prevent damage: Each shipment contains essential information:

What is battery module assembly process?

The battery module assembly process is a crucial step in the battery pack manufacturing process, where individual battery cells are grouped into modules. This stage enhances efficiency, safety, and performance by integrating electrical connections, thermal management systems, and safety features.

More industry content

- Photovoltaic panels for solar energy utilization

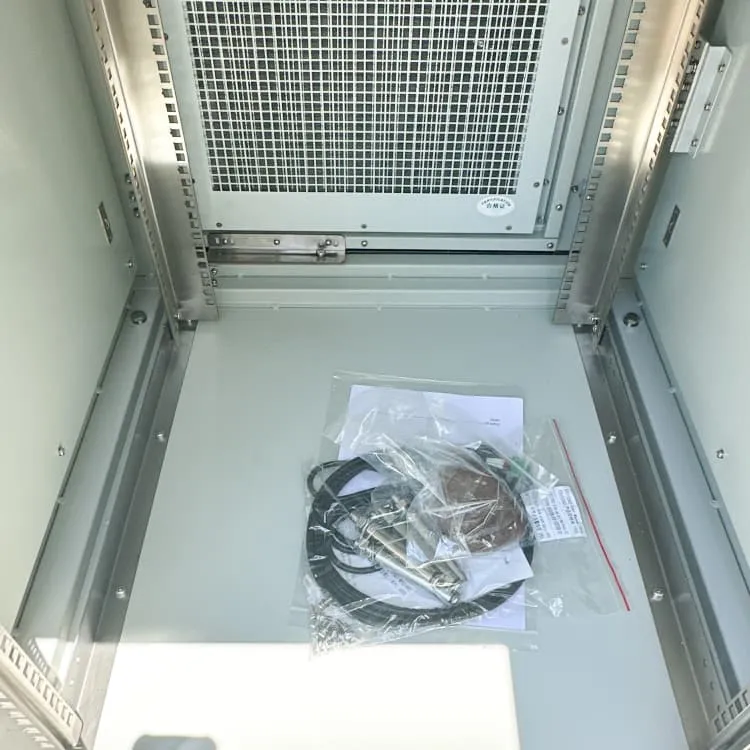

- South Sudan outdoor battery cabinet BMS module

- Ukrainian container emergency power generation equipment

- Container power generation installation case

- The use of aluminum-based lead-carbon energy storage batteries

- Jordanian solar photovoltaic power generation manufacturers

- What is the price of energy storage projects

- How many watts of solar panels support fast charging

- Stackable Energy Storage Cabinet Solution

- 4-in-1 outdoor power supply

- Swedish solar power system

- Container battery energy storage system price

- How many panels are required per square meter

- Monaco Solar Photovoltaic Panel Inverter

- Austria Solar Off-Grid Inverter

- How big a photovoltaic panel is needed for 1kw solar power generation

- How many inverters does photovoltaic have

- Battery layout of energy storage container

- Solar panel fabric

- How to increase or decrease the power supply of communication base station

- Solar inverter parallel connection

- Is industrial energy storage power useful